Upper Eccentric Hemisphere Valve

Upper Eccentric Hemisphere Valve

Nominal diameter: DN100 ~ 1400mm

Nominal: PN1.0 ~ 1.6MPa

Material: Carbon steel WCB / CF8 stainless

Medium: natural gas, coal gas, liquefied petroleum gas, crude oil, heavy

Temperature: ≤425 ℃

Method Blue Connection Size: GB / T 9113.1-2000.ASME / ANSI 16.5

Eccentric hemispherical valve Product Description:

The eccentric hemispherical valve is suitable for applications such as sewage treatment, pulp, alumina, urban heating, oil, natural gas, liquid solid two-phase mixing or easy chemical crystallization. Can be replaced: general valve, petrochemical valve, gas dedicated valve, slurry special valve, coal ash and other special valves.

Eccentric hemispherical valve with eccentric structure of the principle, through the transmission to achieve tightening, adjustment, the purpose of closure. Double eccentric structure ball valve in the open when the ball hidden in the valve chamber, the flow surface is large, close the valve core spherical along the seat gradually, with shear function, effectively remove the fouling obstacles to achieve a reliable seal.

Eccentric hemispherical valve works:

This series of ball valve is the essence of the traditional ball valve crystal changes, it is the metal ball crown fixed on the eccentric sphere, through the eccentric crankshaft 90 degree rotation, to achieve the valve opening and closing, and metal ball sealing surface contact metal valve seat Axial and radial floating, to compensate for the ball crown and valve seat valve. Simple and reliable construction and effective sealing so that it can not only advantage to replace the gate valve, and can be applied to the system can not be used. Can be applied to the oil, chemical, power and metallurgical industries, the core technology is the first domestic, it is unique design, novel structure. Its structure adopts the principle of eccentricity compacting through the transmission mechanism to achieve the purpose of tightening, adjusting and closing. The sealing pair is a metal surface ring with a hard surface contact seal. When the double eccentric structure is opened, the spool is located in the ball chamber, The valve is not washed, closed when the spool is not washed, open the valve core spherical along the seat gradually, effectively remove the fouling obstacles to achieve a reliable seal. It is particularly effective for mixed flow transport of solid phase fouling solids.

Eccentric hemispherical valve Features:

1, sealed tightly, transporting harmful gases up to zero leakage.

2, the valve hemisphere with bimetallic, base metal on the welding of different alloys, the valve seat for the corresponding surfacing by a special treatment, sealing surface combination into anti-corrosion, wear, high strength and other types to meet the needs of different occasions The

3, the seal of the spool to leave the amount of compensation, when the valve to do wear, turn off and then turn a little, any reliable seal, to extend the service life. In addition, the user will squeeze the nut to twist off, adjust or replace the valve seat is still available, to avoid the valve seal failure, the whole drawbacks.

4, the structure of the principle of eccentricity through the transmission mechanism to achieve tightening, adjustment, closing the purpose of sealing the metal surface ring with a hard surface contact seal, double eccentric structure in the open when the spool is located in the ball room, the flow section , And the valve is not washed, closed when the spool is not washed, open the valve core spherical along the seat gradually, effectively remove the fouling obstacles to achieve a reliable seal. It is particularly effective for mixed flow transport of solid phase fouling solids.

Main performance specifications:

Nominal | 0.6 | 1.0 | 1.6 | 2.0 | 2.5 | 4.0 | 5.0 | 6.4 | 10 | |

Shell test pressure | 0.9 | 1.5 | 2.4 | 3.0 | 3.8 | 6.0 | 7.5 | 9.6 | 15 | |

High pressure seal testing | 0.66 | 1.1 | 1.8 | 2.2 | 2.8 | 4.4 | 5.5 | 7.1 | 11 | |

Applicable medium and temperature ℃ | DYQ40 type | Water, steam, pulp and other solutions | ||||||||

DYQ40 type | Natural gas, coal gas, liquefied | |||||||||

DYQ40 type | Solution, pulp, alumina powder, pulverized coal, coal ash, dusty gas, waste residue, etc. | |||||||||

☆ erection of eccentric semi-ball valve main parts of the material and code materials and codes of main parts

Part | DYQ40 type | DYQ40 type | DYQ40 type |

Body | Carbon WCB / stainless CF8 | Carbon WCB / stainless CF8 | Carbon WCB / stainless CF8 |

Stem | 2Cr13 / 304 | 2Cr13 / 304 | 2Cr13 / 304 |

Plug seal sub | WCB / CF8 + Cr | WCB / CF8 + hardened | Special hardening alloy steel |

Sealing seat | PTFE / Molon | WCB / CF8 + hardened | Special hardening alloy steel |

☆: 1, the product flange size press GB / T 9113.1-2000.ASME projecting flange surface / 16.5 under the ANSI;

2, the length of the structure with reference to GB 12221-2005, the predetermined ASNE B16.10;

3, manufactured And acceptance of technical conditions with reference to GB12237-89, API 6D;

4, the pressure test by JB / T9092-1999, GB / T13927-92, AP1598 requirements.

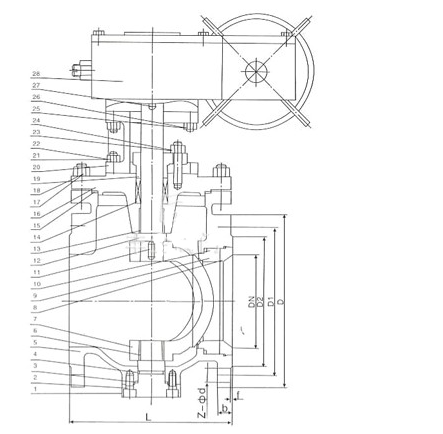

Nominal pressure | Nominal diameter | Size (mm) | |||||||

L | D | K | d | b | z-d0 | Hw | Hd | ||

1.0MPa | 100 | 229 | 220 | 180 | 156 | 22 | 8-φ18 | 330 | 380 |

125 | 254 | 210 | 210 | 184 | 22 | 8-φ18 | 345 | 405 | |

150 | 267 | 240 | 240 | 211 | 24 | 8-φ22 | 370 | 440 | |

200 | 292 | 295 | 295 | 266 | 24 | 8-φ22 | 405 | 470 | |

250 | 330 | 350 | 350 | 319 | 26 | 12-φ22 | 480 | 540 | |

300 | 403 | 400 | 400 | 370 | 26 | 12-φ22 | 520 | 580 | |

350 | 430 | 460 | 460 | 429 | 26 | 16-φ22 | 570 | 630 | |

400 | 530 | 515 | 515 | 480 | 26 | 16-φ26 | 630 | 710 | |

450 | 580 | 565 | 565 | 530 | 28 | 20-φ26 | 690 | 770 | |

500 | 660 | 620 | 620 | 582 | 28 | 20-φ26 | 740 | 820 | |

600 | 840 | 725 | 725 | 682 | 34 | 20-φ30 | 840 | 940 | |

700 | 900 | 840 | 840 | 794 | 34 | 24-φ30 | 960 | 1040 | |

800 | 1000 | 950 | 950 | 901 | 36 | 24-φ33 | 1080 | 1180 | |

900 | 1100 | 1050 | 1050 | 1001 | 38 | 28-φ33 | 1190 | 1280 | |

1000 | 1200 | 1160 | 1160 | 1112 | 38 | 28-φ36 | 1310 | 1420 | |

1200 | 1300 | 1380 | 1380 | 1328 | 44 | 32-φ39 | 1420 | 1530 | |

1400 | 1500 | 1590 | 1590 | 1530 | 48 | 36-φ42 | 1540 | 1650 | |

1.6MPa | 100 | 229 | 180 | 180 | 156 | 22 | 8-φ18 | 330 | 380 |

125 | 254 | 210 | 210 | 184 | 22 | 8-φ18 | 345 | 405 | |

150 | 267 | 240 | 240 | 211 | 24 | 8-φ22 | 370 | 440 | |

200 | 292 | 295 | 295 | 266 | 24 | 12-φ22 | 405 | 470 | |

250 | 330 | 355 | 355 | 319 | 26 | 12-φ26 | 480 | 540 | |

300 | 403 | 410 | 410 | 370 | 28 | 12-φ26 | 520 | 580 | |

350 | 430 | 470 | 470 | 429 | 30 | 16-φ26 | 570 | 630 | |

400 | 530 | 525 | 525 | 480 | 32 | 16-φ30 | 630 | 710 | |

450 | 580 | 650 | 585 | 548 | 40 | 20-φ30 | 690 | 770 | |

500 | 660 | 770 | 650 | 609 | 44 | 20-φ33 | 740 | 820 | |

600 | 840 | 840 | 770 | 720 | 54 | 20-φ36 | 840 | 940 | |

700 | 900 | 950 | 840 | 794 | 40 | 24-φ36 | 960 | 1040 | |

800 | 1000 | 1050 | 950 | 901 | 42 | 24-φ39 | 1080 | 1180 | |

900 | 1100 | 1125 | 1050 | 1001 | 44 | 28-φ39 | 1190 | 1280 | |

1000 | 1200 | 1255 | 1170 | 1112 | 46 | 28-φ42 | 1310 | 1420 | |

1200 | 1300 | 1485 | 1390 | 1328 | 52 | 32-φ48 | 1420 | 1530 | |

1400 | 1500 | 1590 | 1590 | 1530 | 58 | 36-φ48 | 1540 | 1650 | |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552