Pneumatic Fixed Ball Valve

Pneumatic Fixed Ball Valve

Nominal Pressure: 1.6MPa-10.0 MPa

Connection Form: Flange Type

Applicable Temperature:-20~+90℃

Body Material: WCB, CF8, CF8M, CF3M

First, Pneumatic Fixed Ball Valve Product Overview

Pneumatic fixed ball valve is composed of angle stroke pneumatic actuator and fixed ball valve. Using the upper and lower valve stem fixed spool (shaft support) and movable seal seat design, the work is more stable. The pneumatic fixed ball valve has the function of automatic compensation. The two-way sealing valve seat has no clearance, and it has a large shear force and self-cleaning function when turning. The flow resistance coefficient is small, the installation is convenient, the operation is reliable, the sealing is good, the adaptability is strong, and the maintenance is simple. Pneumatic fixed ball valve can be equipped with travel limit switch, solenoid valve, pressure reducing valve, air filter and other accessories. The control switch gas source is in the range of 0.4MPa-0.7MPa, and sends two pairs of passive contact signals to indicate the valve switch. At present the pneumatic fixed ball valve is widely used in petroleum and chemical industry, metallurgy, environmental protection, water supply and drainage, electric power, light industry, papermaking, high-voltage equipment and other industrial automatic control system for centralized remote control or local control.

Two, Pneumatic Fixed Ball Valve Product Characteristics

1, Pneumatic fixed ball valve with fixed ball design. The moving parts of the friction coefficient and small material, operation torque small flexible use.

2, Pneumatic fixed ball valve adopts full diameter or shrinkage, the flow resistance is small.

3, Hard seal pneumatic fixed ball valve adopts two-way metal movable sealing structure, with automatic compensation and self-cleaning function, sealing performance is stable.

4, The use of double movable seal seat design, with two-way sealing function, installation without considering the media flow direction.

5, With anti-static structure design. A conductive spring is arranged between the valve body and the valve body and between the valve rod and the ball, so as to avoid the electrostatic ignition and ignite the flammable medium.

6, With arson function design. In the case of emergency fire, the metal seal is formed on the sealing surface of the valve seat.

[Optional Attachment]:

1, Cut off accessories: single electronic controlled solenoid valve, double electronic controlled solenoid valve, limit switch return device.

2, Adjustable accessories: Electrical positioner, pneumatic positioner, electrical converter.

3, Gas processing accessories: air filter pressure reducing valve, gas source treatment sanlian.

4, Manual mechanism: HVSD hand operating mechanism.

Three. Other Parameters Of Pneumatic Fixed Ball Valve

1, valve body

| Type of Body | Two Stage Casting Valve Body |

| Nominal Diameter | DN50~1000mm |

| Nominal Pressure | PN1.6、2.5、4.0、6.4、10.0 MPa;ANSI 150 300 600 900 LB;JIS 10 20 30 40 K |

| Connection Form | Flange type |

| Flange Standard | JIS、ANSI、GB、JB、HG |

| Bonnet Form | One-piece |

| Gland Type | Bolt Pressing Type |

| Sealing Filler | V PTFE Packing, Impregnated PTFE Asbestos Filler, Asbestos Textile Filler, Graphite Filler |

2、Valve Internals

| Spool Form | O-type Fixed Ball Type Valve Core |

| Flow Characteristics | Approximately Fast Open Type |

3、Executive Mechanism

| Actuator Type | GT, SR, ST, AT, AW series of single and double acting pneumatic actuators |

| Gas supply Pressure | 0.4~0.7MPa |

| Air Connection | G1/4"、G1/8"、G3/8"、G1/2" |

| Ambient Temperature | -20~+90℃ |

| Action Form | Single acting actuator: gas shut off (B) - valve opening (FO) when gas is out of breath; gas open (K) - valve position off (FC) when air is out of breath Double acting actuator: gas shut off (B) - valve position holding (FL) when gas lost; gas open (K) - valve position holding (FL) when lost air |

| Fitting accessories | Positioner, solenoid valve, air filter pressure reducer, retaining valve, stroke switch, valve position conveyor, hand wheel mechanism, etc. |

Four, Pneumatic Fixed Ball Valve Main Parts And Materials

| 1 | Base | WCB、CF8、CF8M、CF3M |

| 2 | Left Valve Body | WCB、CF8、CF8M、CF3M |

| 3 | Lower Valve Shaft | 2Cr13、304、316、316L |

| 4 | Right Valve Body | WCB、CF8、CF8M、CF3M |

| 5 | Sphere | 2Cr13、304、316、316L |

| 6 | Seal Ring | PTFE、PPL、304、316、316L |

| 7 | Spring | 65Mn、Stainless Steel |

| 8 | pin | 25、35、45 |

| 9 | Upper Valve Shaft | 2Cr13、304、316、316L |

| 10 | Bracket | WCB、CF8、CF8M、CF3M |

| 11 | Packing Plate | WCB、CF8、CF8M、CF3M |

| 12 | Actuator | Provide Configuration According To Customer Requirements |

Five, Pneumatic Fixed Ball Valve Main Performance Indicators

| Nominal Diameter DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Allowable Pressure Difference(MPa) | ≤ Nominal Pressure | |||||||||||||||||

| Range Of Action | 0~90° | |||||||||||||||||

| Leakage Volume Q | Soft Seal VI class, hard seal IV class, conform to ANSI B16.104 standard | |||||||||||||||||

| Basic Error | With Locator: Less than full stroke±2% | |||||||||||||||||

| Return Difference | With Locator: Less than 2% of the total journey | |||||||||||||||||

Six, The Main Performance Specification Of Pneumatic Fixed Ball Valve

| Test Pressure(MPa) | Nominal Pressure(MPa) | Pressure Stage(class) | JIS(K) | |||||||

| 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 150 | 300 | 600 | 10K | 20K | |

| Strength Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 3.0 | 7.5 | 16.5 | 2.4 | 3.8 |

| Sealing Test | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 2.2 | 5.5 | 12.1 | 1.5 | 2.8 |

| Airtight Test | 0.4~0.7MPa | |||||||||

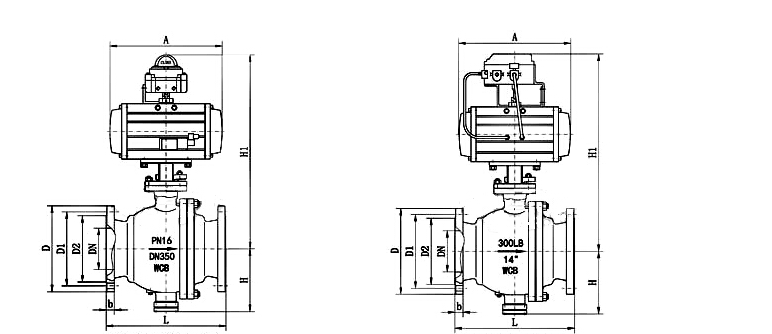

| Nominal Diameter DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 |

| L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | 630 | 750 |

| H | - | - | - | - | - | - | 335 | 385 | 430 | 470 | 590 | 700 | 780 | 950 |

| H1 | According to the executing agency, the configuration actuator is different, the connection size is different | |||||||||||||

| A | ||||||||||||||

| D | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 705 | 840 | 910 |

| D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 650 | 770 | 840 |

| D2 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | 435 | 485 | 608 | 718 | 788 |

| n-φd | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 | 12-22 | 12-26 | 12-26 | 12-26 | 12-30 | 12-34 | 12-41 | 12-41 |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552