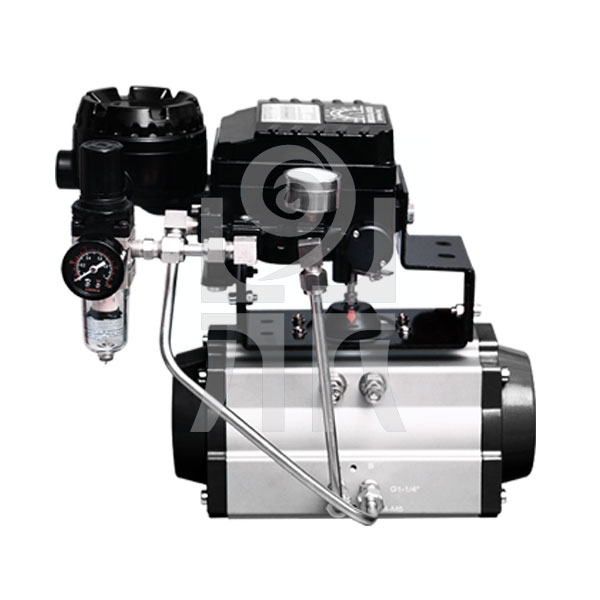

AT Pneumatic Actuator

AT Pneumatic Actuator

Stroke Range: 0-90 degrees

Protection Class: IP67

Control Mode: Double Acting, Single Acting normally closed, Single acting normally open

Structure: Rack and Pinion Piston Type

Valve Available: Butterfly Valve, Ball Valve, Air Valve

Surface Treatment: Hard Oxygen Anode

Accessories: Solenoid Valve, Air Filter Pressure Reducing Valve, Echo Device, Hand Wheel, Electrical Positioner

1. AT Pneumatic Actuator Product Overview

At new pinion and rack type pneumatic actuators through CAD three-dimensional model innovation optimization design, beautiful appearance, compact, modern shape;The utility model materials and new processes are adopted to make the quality and performance of the products more reliable.Multi-specification selection is more economical and affordable;The products are in full compliance with international standards and specifications to meet the present and future needs.

2. AT Pneumatic Actuator Product Features

1, Rack and Pinion double piston symmetrical structure design, fast and stable action, high precision, large output power, through a simple change of piston assembly position can be obtained in the opposite direction of rotation.

2. Extruded high-quality aluminum alloy cylinder body, the inner hole and outer surface of the precision machining are hard anodized (anodized + Teflon coating under special circumstances), long service life, low friction coefficient.

3, integrated design, all the double acting and single acting actuator type number, have the same cylinder and end cover, it is convenient to change the mode of action by adding spring or removing spring.

4, The combination type preloading safety spring group, whether in the assembly process or in the use of the site, can be convenient and safe installation or increase or decrease the number of springs.

5. Two separate adjusting screws on the external side are more accurate and convenient for the actuator installed on the valve. The opening and closing position of the regulating valve is more accurate.

6, Multi-function position indicator, field visual indication, in line with VID/ Vie3845, NAMUR standard slot, can install and output all accessories, such as limit switch box, electrical locator, position sensor (Pepper + Fuck, Turck).

7, Air source interface in line with NRMAR standard, can be directly installed NUMAR standard solenoid valve.

8, The composite bearing bush and piston guide ring on the back of the rack and the bearing of the output shaft to prevent the metal-to-metal friction, and increase lubrication, so that the low friction, prolong the service life.

9. All fasteners are made of stainless steel for long-term corrosion resistance.

10, The connection part conforms to the new international standard ISO5211, DIN3337 (F03-F25), so that the production and installation have interchangeability and versatility.

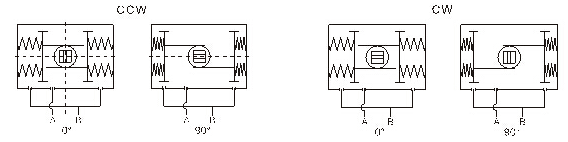

3. Working Principle Of Double Acting Type(ATD)

CCW:

A Inlet. Compressed air overcomes the spring force.

Pushing the piston outward movement, the output shaft of the actuator rotates counterclockwise (0°→90°), B outlet exhaust;

The actuator loses air, the piston moves inward under the action of the spring force, the output shaft of the actuator rotates clockwise (90°→0°), and the A port exhausts.

CW:

A Inlet Air, compressed air to overcome the spring force.

Pushing the piston outward movement, the output shaft of the actuator rotates clockwise (0°→90°), B outlet exhaust;

The actuator loses air. The piston moves inward under the action of a spring force.

The output shaft of the actuator rotates counterclockwise (90°→0°), and outlet A exhausts.

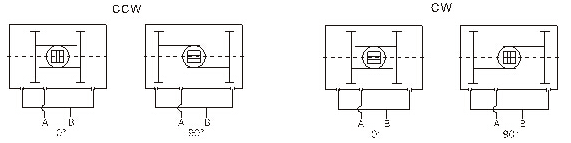

4. Working Principle Of Single ActingType(ATE)

CCW:

Port A intake, compressed air to push the piston outward movement, so that the actuator output shaft counterclockwise rotation (0°→90°), port B exhaust.

Port B inlet, compressed air to push the piston inward movement, so that the actuator output shaft clockwise rotation (90°→0°), port A exhaust.

CW:

A inlet, compressed air to push the piston outward movement, so that the actuator output shaft clockwise rotation (0°→90°), B outlet exhaust.

Port B inlet, compressed air to push the piston inward movement, so that the actuator output shaft counterclockwise rotation (90°→0°), port A exhaust.

5.AT Pneumatic Actuator Technical Parameters

| Technical Parameters | |||

| Spare Parts | Anticorrosion Grade | ||

| A | B | ||

| Cylinder Block | Anodic Hardening | Manual operation mechanism can realize manually open and close the valve | |

| End Cap | Metallic Polyester Coating | Teflon Coating | |

| Output Shaft | Electroless Nickel Plating on Carbon Steel | Electroless Nickel Plating on Carbon Steel or Stainless Steel | |

| Use Occasion | General Occasions | General Occasions or Low Concentration Acidic Environment | |

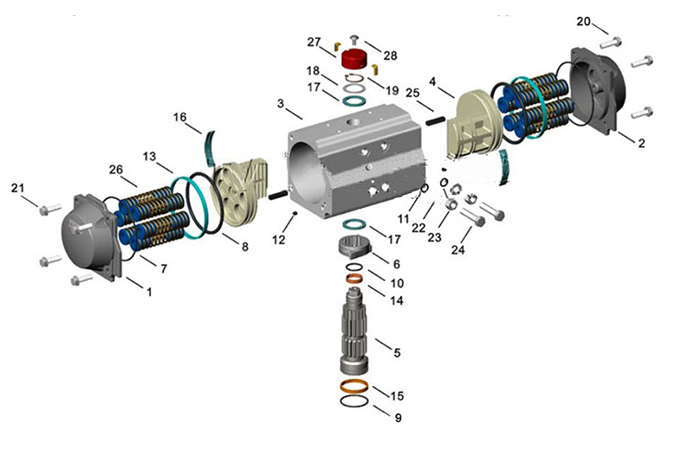

| Anatomical Parameters | ||||

| Part Number | Quantity Per Set | Part Name | Standard Materials | Selection Of Materials |

| 01 | 1(1) | Left End Cap | Die-cast Aluminium Alloy | Stainless Steel |

| 02 | 1(1) | Left End Cap | Die-cast Aluminium Alloy | Stainless Steel |

| 03 | 1 | Cylinder Block | Extruded Aluminum alloy | Stainless Steel |

| 04 | 2 | Piston | Die-cast Aluminium Alloy | - |

| 05 | 1 | Output Shaft | carbon Steel | Stainless Steel |

| 06 | 1 | Adjusting Cam | Stainless Steel | - |

| 07 | 2 | O-ring(End cover) | Nitrile Rubber | Fluoro or Silicone rubber |

| 08 | 2 | O-ring(Piston) | Nitrile Rubber | Fluoro or Silicone rubber |

| 09 | 1 | O-ring(Bottom of output shaft) | Nitrile Rubber | Fluoro or Silicone rubber |

| 10 | 1 | O-ring(top of output shaft) | Nitrile Rubber | Fluoro or Silicone rubber |

| 11 | 2 | O-ring(Adjusting bolt) | Nitrile Rubber | Fluoro or Silicone rubber |

| 12 | 2 | Plug Head (cylinder block) | Nitrile Rubber | Fluoro or Silicone rubber |

| 13 | 2 | Bearing (Piston) | Fluorocarbon Composites | - |

| 14 | 1 | Bearing (Top of output shaft) | Nylon 46 | - |

| 15 | 1 | Bearing (Top of output shaft) | Nylon 46 | - |

| 16 | 1 | Guide Bearing(Piston back) | Nylon 46 | - |

| 17 | 2 | Thrust Bearing (output shaft) | Nylon 46 | - |

| 18 | 2 | Gasket (output shaft) | Nylon 46 | - |

| 19 | 1 | Elastic Retaining Ring | Stainless Steel | - |

| 20 | 8/12/16(2) | End Cover Bolt | Stainless Steel | - |

| 21 | 8/12/16(2) | End Cover Gasket | Stainless Steel | - |

| 22 | 2 | Gaskets | Stainless Steel | - |

| 23 | 2 | Nut | Stainless Steel | - |

| 24 | 2 | Adjusting Bolt | Stainless Steel | - |

| 25 | 2 | Guide Block | Nylon66+30%FG | - |

| 26 | 5-12 | Spring Components | Alloy spring Steel | - |

| 27 | 1 | Position Indicator | PP+30%FG | - |

| 28 | 1 | Screw | Stainless Steel | - |

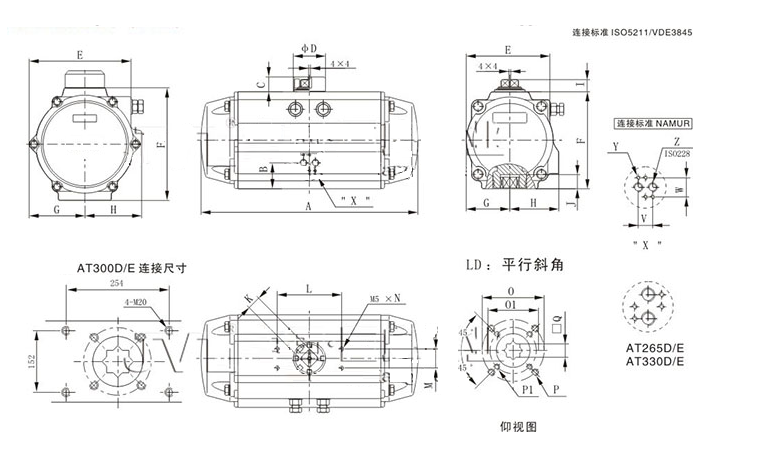

| Main dimensions(mm) | ||||||||||||||

| Model | AT50 | AT63 | AT75 | AT88 | AT100 | AT115 | AT125 | AT145 | AT160 | AT180 | AT200 | AT240 | AT265 | AT330 |

| D/E | ||||||||||||||

| ISO flange | F04 | F05 | F05-07 | F05-07 | F07-10 | F07-10 | F07-10 | F10-12 | F10-12 | F12 | F14 | F16 | F16 | F16 |

| A | 140.5 | 158.5 | 210.5 | 247.5 | 268.5 | 315 | 345 | 408.5 | 437.5 | 487 | 546 | 633 | 728 | 876 |

| B | 26.5 | 30 | 30.5 | 32.5 | 37.5 | 42.5 | 45 | 47.5 | 52 | 58.5 | 62.5 | 78.5 | 165 | 187 |

| C | 20 | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 50 | 50 | 50 | 50 | 50 |

| φD | 40 | 40 | 40 | 40 | 40 | 56 | 56 | 65 | 65 | 80 | 80 | 115 | 115 | 115 |

| E | 59 | 72 | 84.5 | 97.5 | 111 | 127 | 136 | 156.5 | 169 | 190.5 | 213 | 251 | 298.5 | 383 |

| F | 69 | 85 | 102 | 115 | 127 | 145 | 157 | 177 | 196 | 220.5 | 245 | 298.5 | 330 | 405 |

| G | 29 | 36 | 42.5 | 49.5 | 56 | 64 | 69.5 | 80 | 88 | 99 | 110 | 131 | 163.5 | 201 |

| H | 41.5 | 47 | 52 | 56.8 | 67 | 77 | 82 | 91.5 | 99 | 105 | 112 | 131 | 166 | 204.5 |

| I | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | 24.5 | 24.5 | 24.5 | 24.5 | 44.5 | 44.5 | 44.5 | 44.5 | 44.5 |

| J min | 12 | 16 | 16 | 19 | 19 | 24 | 24 | 29 | 29 | 29 | 38 | 38 | 48 | 57 |

| k | 11 | 11 | 17 | 17 | 17 | 27 | 27 | 27 | 27 | 36 | 36 | 36 | 36 | 36 |

| L | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 130 | 130 | 130 | 130 | 130 |

| M | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| N | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| EO1 | 42 | 50 | 50 | 50 | 70 | 70 | 70 | 102 | 102 | 125 | 140 | 165 | 165 | 165 |

| EO | - | - | 70 | 70 | 102 | 102 | 102 | 125 | 125 | - | - | - | - | - |

| P1 | 4-M6 | 4-M6 | 4-M6 | 4-M6 | 4-M8 | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M12 | 4-M16 | 4-M20 | 4-M20 | 4-M20 |

| P | - | - | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M10 | 4-M12 | 4-M12 | - | - | - | - | - |

| 口Q | 11 | 14 | 14 | 17 | 17 | 22 | 22 | 27 | 27 | 27 | 36 | 36 | 46 | 55 |

| V | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 40 | 40 | 40 |

| W | 32 | 32 | 32 | 32 | 32 | 32.9 | 32 | 32 | 32 | 32 | 32 | 45 | 45 | 45 |

| Y | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M5x8 | M6x10 | M6x10 | M6x10 |

| Z | 1/8" | 1/8" | 1/8" | 1/8" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 1/4" | 3/8" | 1/2" | 1/2" |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552